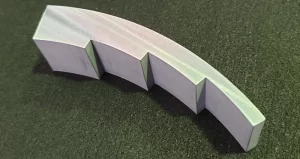

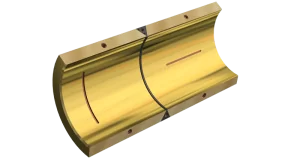

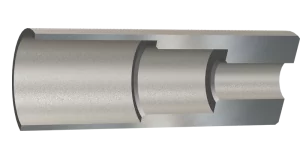

To achieve this, various technologies are commonly used. Because of the complexities of some shapes – perhaps being straight, angled, curved, concave or convex either blind or through – technologies, such as EDM (wire and sinker) and CNC machining are ideal.

These custom calibration blocks can be used for various NDT methods, such as:

- Eddy Current Testing (ET)

- Ultrasonic Testing (UT)

- Time of Flight Diffraction (TOFD)

- Phased Array (PA)

- Advanced Ultrasonic Testing (A-UT)

The SixDe Approach to Calibration Blocks

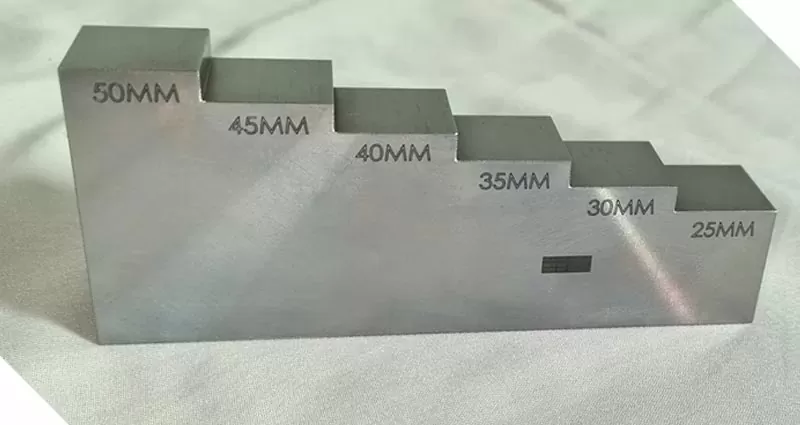

As with all our precision engineering processes, the creation of calibration blocks begins with a design meeting to understand your requirements. This in-depth discovery allows accuracy from the outset. All our calibration projects conform to ASE Section V specifications.

When you partner with SixDe for your calibration block needs, you benefit from:

- Exacting standards that can achieve virtually any specification of defects. Examples include flat bottom holes, micro EDM notches, side drilled holes, corrosion simulation, drilled slots, zipper cracks, round bottom holes/pits etc.

- We create calibration blocks of all sizes, up to 200kgs

- SixDe can produce both commonly used block geometry (fish-tail, eddy current notch, IIW type I & II) or any custom block or plate necessary.

- The complete SixDe service model. This begins with first contact with our customer service team to organise an expert design consultation and culminates with on-time delivery

- Fast, economical and accurate production

- The use of cutting-edge precision machining technology

- All processes used conform to all necessary Australian and international standards

In addition, SixDe customers have the added security of dealing with a Perth-based Australian company. We’re ideally situated to provide the highest quality, yet local, service for Western Australian businesses. However, our reach is extensive, with the capacity and reach for the wider Aussie market and internationally.

Another welcome advantage is our wholly in-house team. SixDe is proud that every element of our precision engineering services is in our control. From customer service to design, production to logistics, we’re responsible for every element of our business model. This means customers can rest assured that they’ll have no worries from outside contractors and the associated potential issues this can bring.

Begin the SixDe Calibration Block Journey

Ready to get in contact? Simply call or email today and we’ll arrange an initial (no-obligation) discussion with a member of our highly experienced design team. This can either take place in our Perth office, at your premises or via a video call.

Our goal for every project is the smoothest journey from the design stage to production. Decades of industry experience not only make us a superior provider, but also means that we appreciate the need for speed and economic viability. We strive to exceed expectations in every element of our service – one of the many reasons that our customers return to us time and again for their precision engineering needs.

SixDe utilises extensive industry know-how across a variety of advanced technologies – such as EDM plunger/sinker, EDM wire cutting and CNC machining – to craft calibration blocks to your exact requirements.

Call us today for a no-obligation chat.